20Feb

Machining Guidelines for alimex cast Aluminium Plate

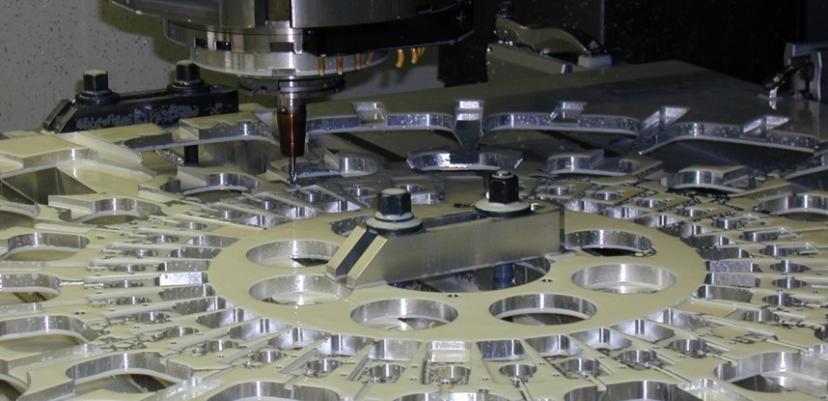

Traditional machining operations, such as turning, milling, and drilling can be easily performed on alimex cast aluminium plates and blocks, with optimum machining being achieved on machines designed for high speed operation.

However careful consideration should be given to the specific properties of the aluminium to be machined:

- The density allows high speeds of rotation and translation as the inertia of aluminium alloy swarf is less than that of steel.

- The modulus of elasticity, which is one third that of steel, requires appropriate holding and clamping arrangements to avoid deformation and distortion.

- Given the high rate of chip removal, the heat generated by the machining process is taken away with the chip — without having the time to diffuse into the metal. Unlike steel, there is no need to provide heat treatment of the stress-free annealing type during machining.

Cutting Force

The specific cutting force needed to machine aluminium is significantly less than that required for steel. For the same section of swarf, the force required for material removal of aluminium is one third of that required for low-carbon steel, allowing for much higher material removal.

Tooling

Modern day tooling specific for aluminium machining is readily available with tooling life being considerably longer than tools for machining steels.

To ensure longevity, optimal machining and material finish;

- Prevent material from bonding to the tools by managing the feeds and speeds as per tooling manufactures recommendations .

- Remove chips from the point of machining.

- Lubricate the cutting edge where applicable and ensure the makeup of cutting fluids is compatible with aluminium.

Machining of Cast Aluminium Plates and Blocks vs. Rolled

With rolled aluminium, even though the material has been stress relieved, there remains some degree of residual stress from the rolling process. This can cause deformation of the material during large stock removal operations.

Generally speaking, the higher the strength of the alloy, the higher the degree of residual stress in the plate. Prior to final machining, the component being manufactured will need to be heat treated to remove the reaming internal residual stress. Only after stress relieving can final machining be completed.

Please note, it is not recommended to thermally stress relieve any heat treated

aluminium, as if this is not controlled correctly, heat treatment could compromise the mechanical properties of the aluminium.

Conversely with cast aluminium block and plate there is no need to rough machine and heat treat the material. During manufacture the billets are cold cast and then sent for processing. There is no rolling of the material, instead horizontal and vertical saws will cut the raw billet to produce the required block or plate, as a result no residual stress is built up within the material.

If machining components from cast aluminium block or plates, the machinist can machine to final dimensions in a single setup.